Fresh water, everywhere*

Reverse osmosis, ultrafiltration, water treatment, desalination and electrodeionisation.

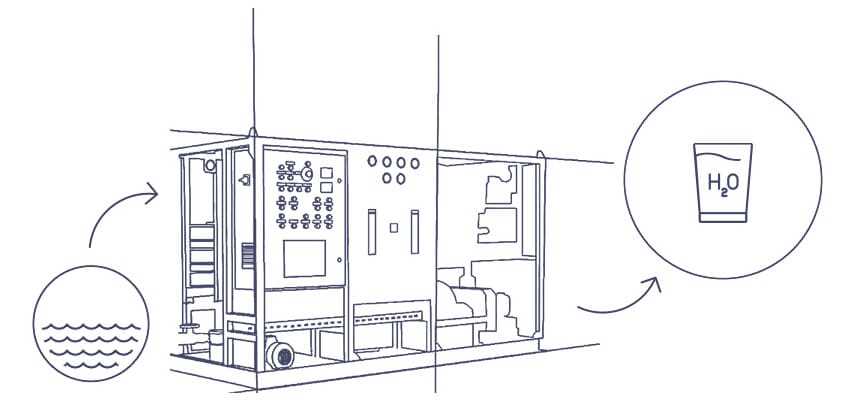

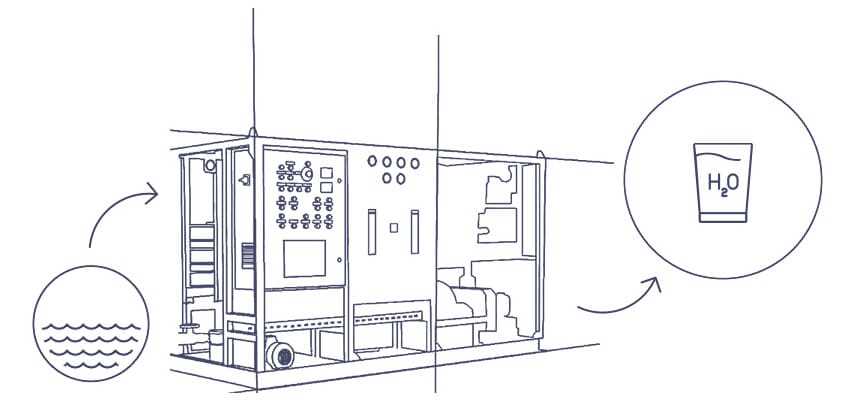

Purify water through reverse osmosis process

-

SLCE watermakers develops standard or tailor-made reverse-osmosis water treatment equipment.

Reverse osmosis is a process that desalts seawater or demineralized brackish water through the use of a semi-permeable membrane. This membrane allows molecules of water (H2O) to pass and blocks the salts as well as all the organic compounds. The water that passes through it is thus purified, mineral and drinkable.

SLCE watermakers

For 35 years, SLCE watermakers has been designing, manufacturing and selling reverse-osmosis water treatment equipment.

The company relies on the use of high quality components, strict manufacturing procedures and a dense and efficient global network of agencies around the world. This allows us to offer a very high level of quality and very reactive services.

SLCE watermakers exports 80% of its production all around the world and offers a complete range of units producing from 1 to over 1500 m3/day of fresh, industrial or ultra pure water .

SLCE watermakers equipment are offered in standard or tailor-made according to your constraints and technical requirements.

SLCE watermakers

Applications

The expertise of SLCE watermakers in the field of reverse osmosis water treatment allows it to meet any type of requirement.

Whether it is desalinators meeting shock resistance constraints in the military navy, very compact units that can be integrated into small vessels, ATEX units in the offshore sector or equipment producing ultra pure water in the nuclear and hospital sectors, SLCE watermakers has the know-how required to carry out any projects.

References

News

View all-

INMEX India: New Partnerships and Exciting Oppo...

As in every edition, we took part in INMEX India, the leading biennial event for the maritime and naval industry. This market, which we have been passionately following for many...

INMEX India: New Partnerships and Exciting Oppo...

As in every edition, we took part in INMEX India, the leading biennial event for the maritime and naval industry. This market, which we have been passionately following for many...

-

Europort 2025

We’re delighted to announce that we’ll be taking part in Europort exhibition 2025 together with our new agent, Venteville B.V.Come and meet us at their booth 1427 to discover our...

Europort 2025

We’re delighted to announce that we’ll be taking part in Europort exhibition 2025 together with our new agent, Venteville B.V.Come and meet us at their booth 1427 to discover our...

-

One technology, multiple uses: Adapting to ever...

At SLCE watermakers, we design and manufacture water treatment systems — watermakers — using reverse osmosis technology. This proven technology, which we master from end to end — from design...

One technology, multiple uses: Adapting to ever...

At SLCE watermakers, we design and manufacture water treatment systems — watermakers — using reverse osmosis technology. This proven technology, which we master from end to end — from design...