SLCE watermakers

We commissioned our first osmosis system into service more than 35 years ago. Since then, SLCE watermakers has developed a full range of equipment producing freshwater or water for industrial processes from seawater, brackish water or mains water. Capacities range from a few hundred liters to more than 1500 m3 per day. More than 10 000 units are in operation all over the world on all type of vessels (yachting, fishing, offshore, commercial and military), land, industrial and offshore applications. Located on the outskirts of Lorient, a Brittany harbor on the Atlantic coast, SLCE watermakers has 3000m² of spacious and functional workshops and offices equipped with the most modern management and organization facilities.

A team at your service

With a team of 50 people, SLCE watermakers is a structured human-sized company able to assist you in any of your projects. This team, half of it being engineers and technicians will follow your project from design to delivery.

SLCE watermakers puts modern and powerful computing resources at your service:

- Simulation and performance calculation softwares,

- CAD 3D stations,

- ERP ensuring project follow-up and product traceability.

Focusing on the customer’s needs, SLCE watermakers implements a policy of continuous improvement which results in the satisfaction of the most demanding users, whatever their specific needs and constraints are.

Manufacturing

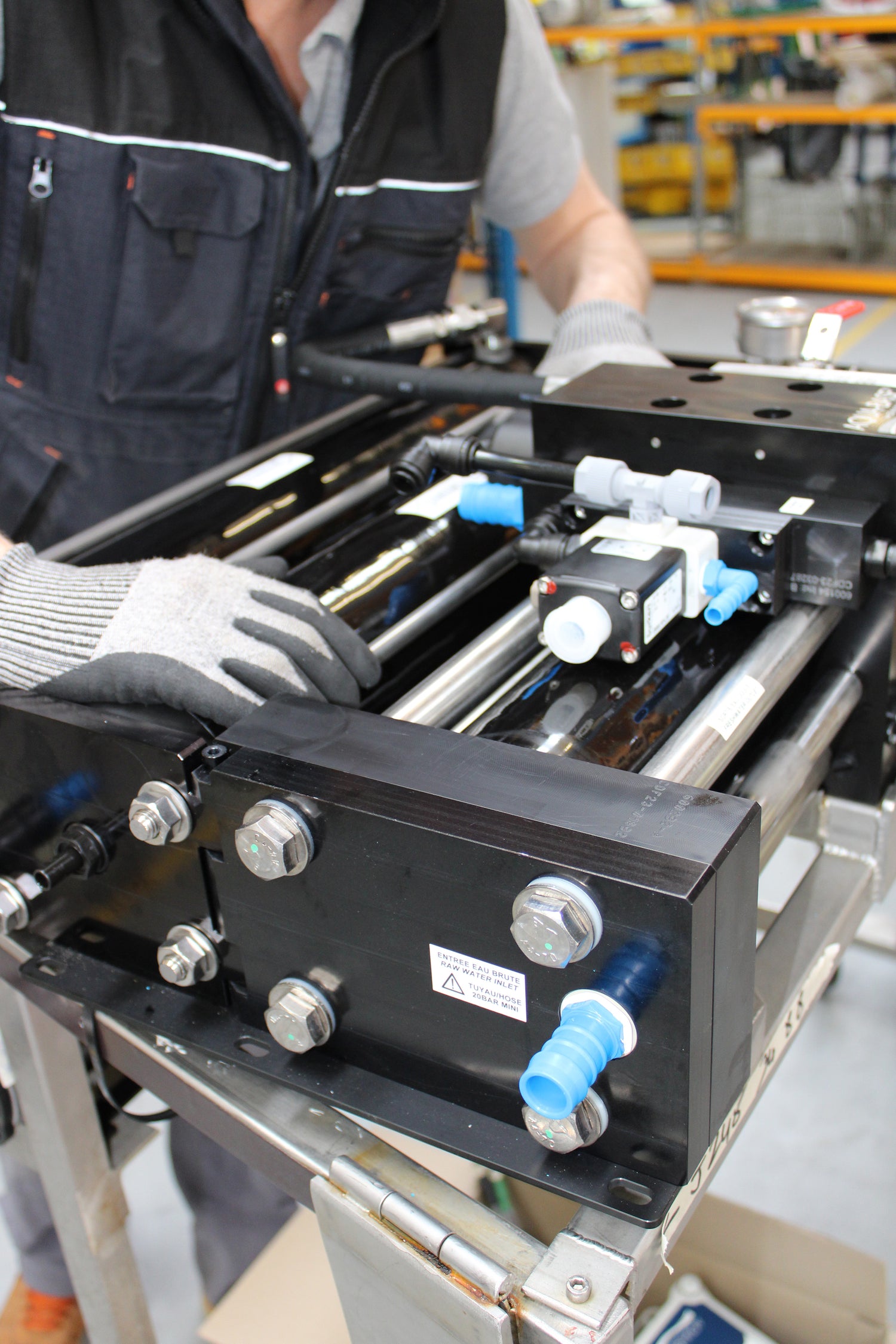

SLCE watermakers has a high-performance manufacturing team working in a spacious and comfortable environment. We have tools and handling equipment adapted to the manufacture and assembly of the most specific desalination units.

The “Lean Manufacturing” implemented by SLCE watermakers on production islands for equipment up to 40 m3/day, makes it possible to provide them, from D + 2 to D + 7 depending on the models.

Each unit is then tested on a test bench in real conditions before shipping.

SLCE watermakers also has a welding workshop for Duplex stainless steel in accordance with EN-ISO 15614-1 and qualified operators.

Logistic

Every day, equipment and spare parts are shipped worldwide.

Each equipment is packed in a shipping container conforming to the standard “NIMP15” or ISO container, then shipped by road, sea or air

SLCE watermakers has been an approved exporter since 2016, thus facilitating the customs procedures of all parties involved in the logistics supply chain.

Quality

From the entry of the components into the warehouse, SLCE watermakers carries out strict control at all stages of production.

All parts delivered by our suppliers are controlled as soon as they are received to certify their conformity; materials are analysed using a mass spectrometer. A barcode system then ensures the traceability of the stored products.

From the simplest to the most complex, all equipment are tested on a test bench before packaging:

- Test with raw water similar to that specified at the order.

- Control of operating parameters: power consumption, conversion rate, pressures, flow rates, conductivity of the water produced…

- Customers are invited to participate in factory acceptance tests where a training session may be associated.

Certifications

SLCE watermakers has been ISO 9001 : 2015 certified since 2007 for all its activities, from design to delivery and training of the users.

SLCE watermakers has also been a NATO supplier, number F9758, for more than 20 years.

French customs have granted SLCE watermakers the status of approved exporter since 2016.

All standard ranges up to 40 m3/day are type approved by BUREAU VERITAS.

The welding procedures carried out internally, qualified by APAVE, comply with the standard NF EN ISO 9606-1 edition 12/2013.