Energie recovery devices (E.R.D.)

In a conventional system, the entire seawater pumped is pressurized. Much of the energy spent for this purpose is dissipated in the discharge.

In an effort to save energy, our recovery devices are a unique asset. They reduce the consumption of the osmosis by transferring the energy available in the reject to the seawater.

We use two proven and recognized recovery devices: one linear and one rotary.

Linear E.R.D.

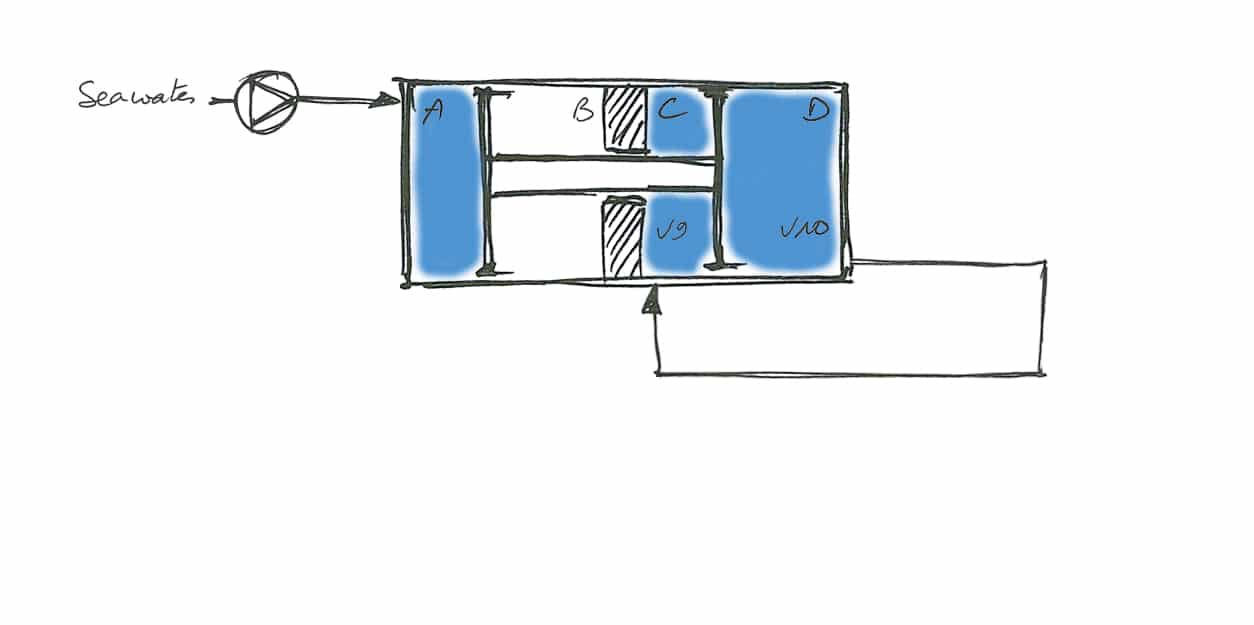

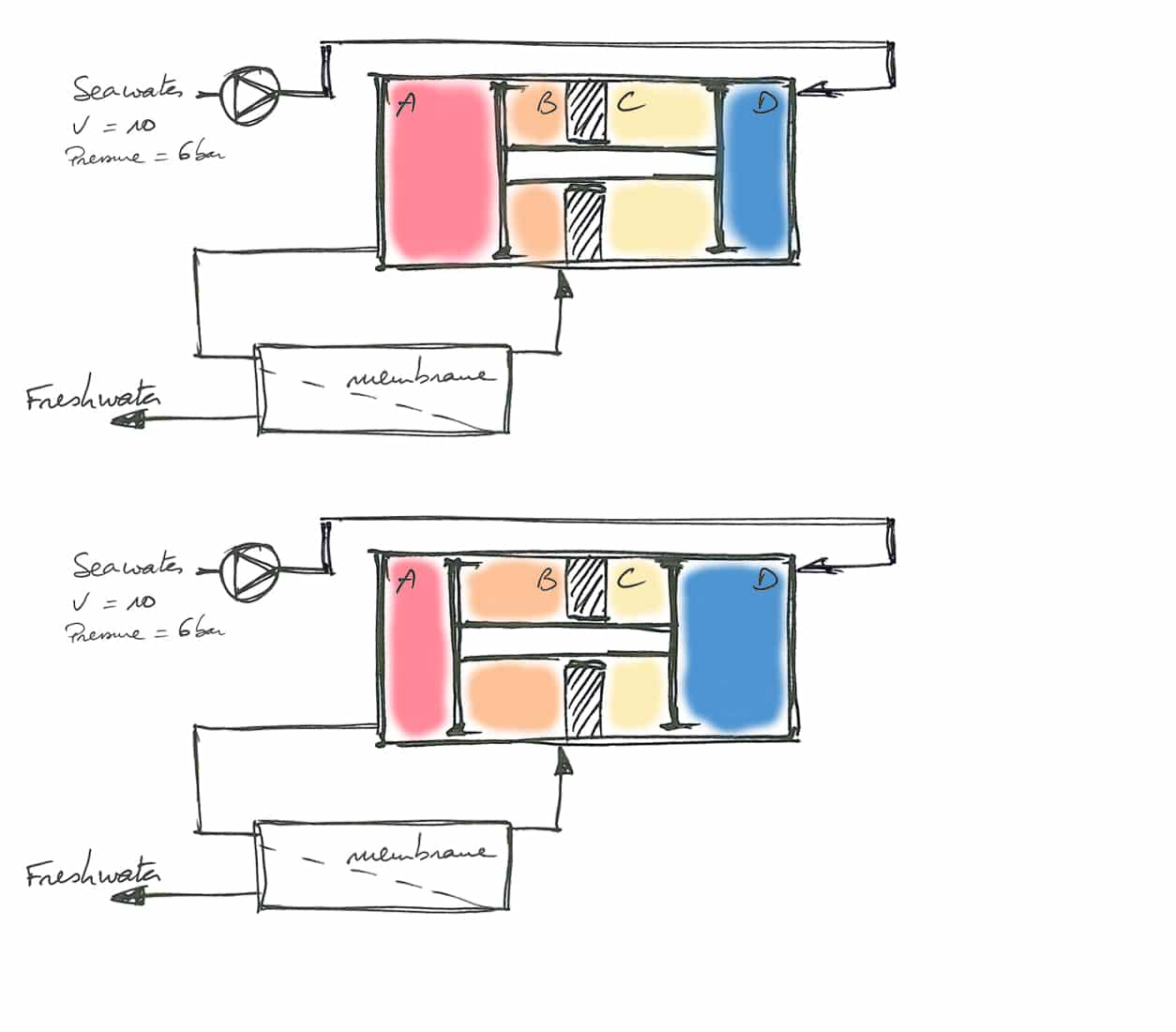

A double sealed piston separates a cylinder into four distinct compartments: A, B, C, and D.

At the beginning of the cycle, chamber D has a volume of 10 and chamber C a volume of 0.

At the end of the cycle, chamber D will have a volume of 0 and chamber C a volume of 9. The missing volume of the chamber C corresponds to the volume occupied by the piston rod.

The chambers C and D are connected and filled (step only necessary for the presentation of the principle of the linear ERD).

A pump feeds chamber A.

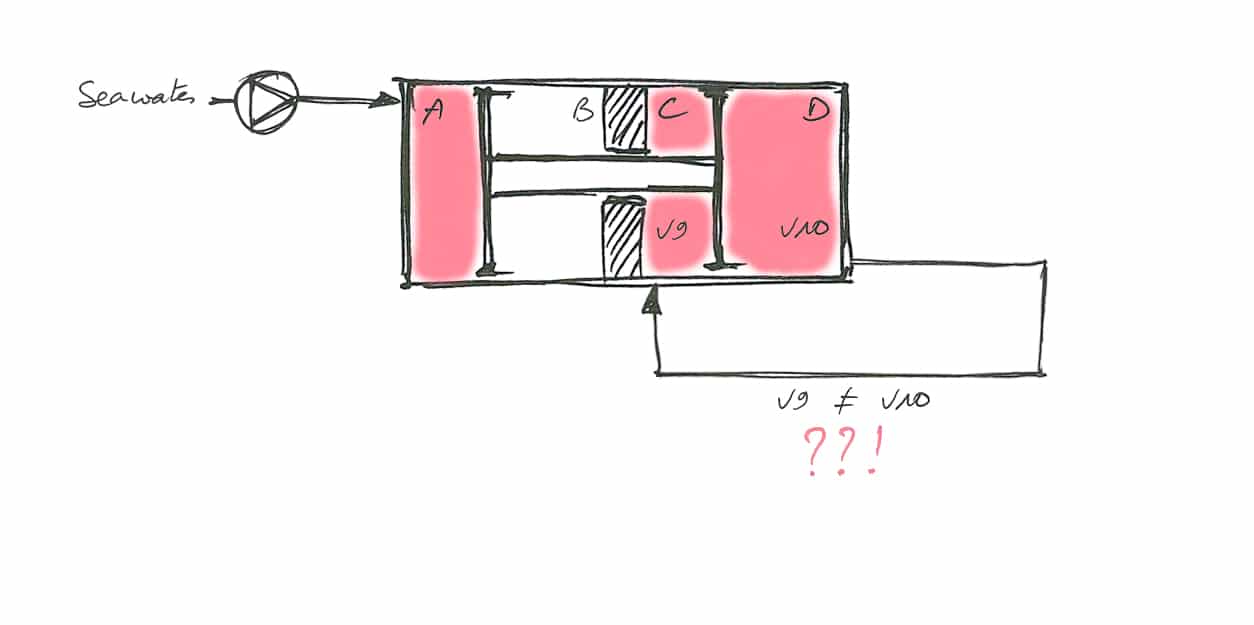

Because of the difference in volume between chamber D and C and the incompressibility of water, the piston is blocked.

Discharging the excess volume would allow the piston to move.

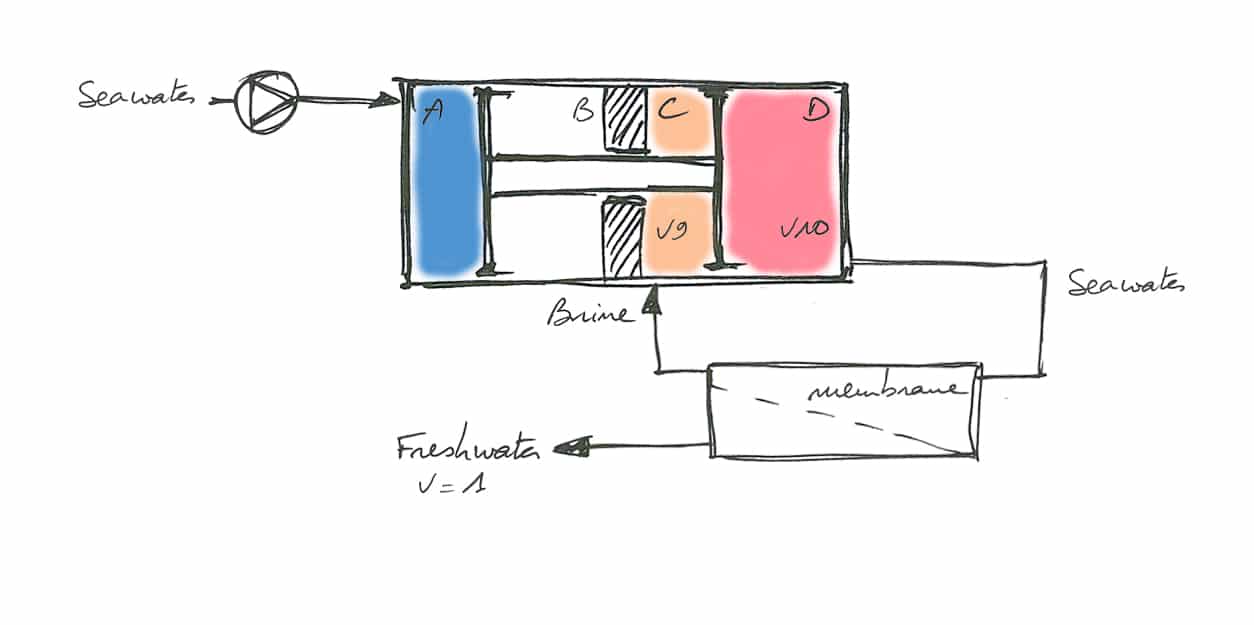

This excess volume is converted into fresh water through a reverse osmosis membrane installed between chambers C and D.

The 10 volumes of water from chamber D are admitted into the membrane.

The membrane thus produces 1 volume of fresh water, the remaining 9 volumes are transferred into chamber C.

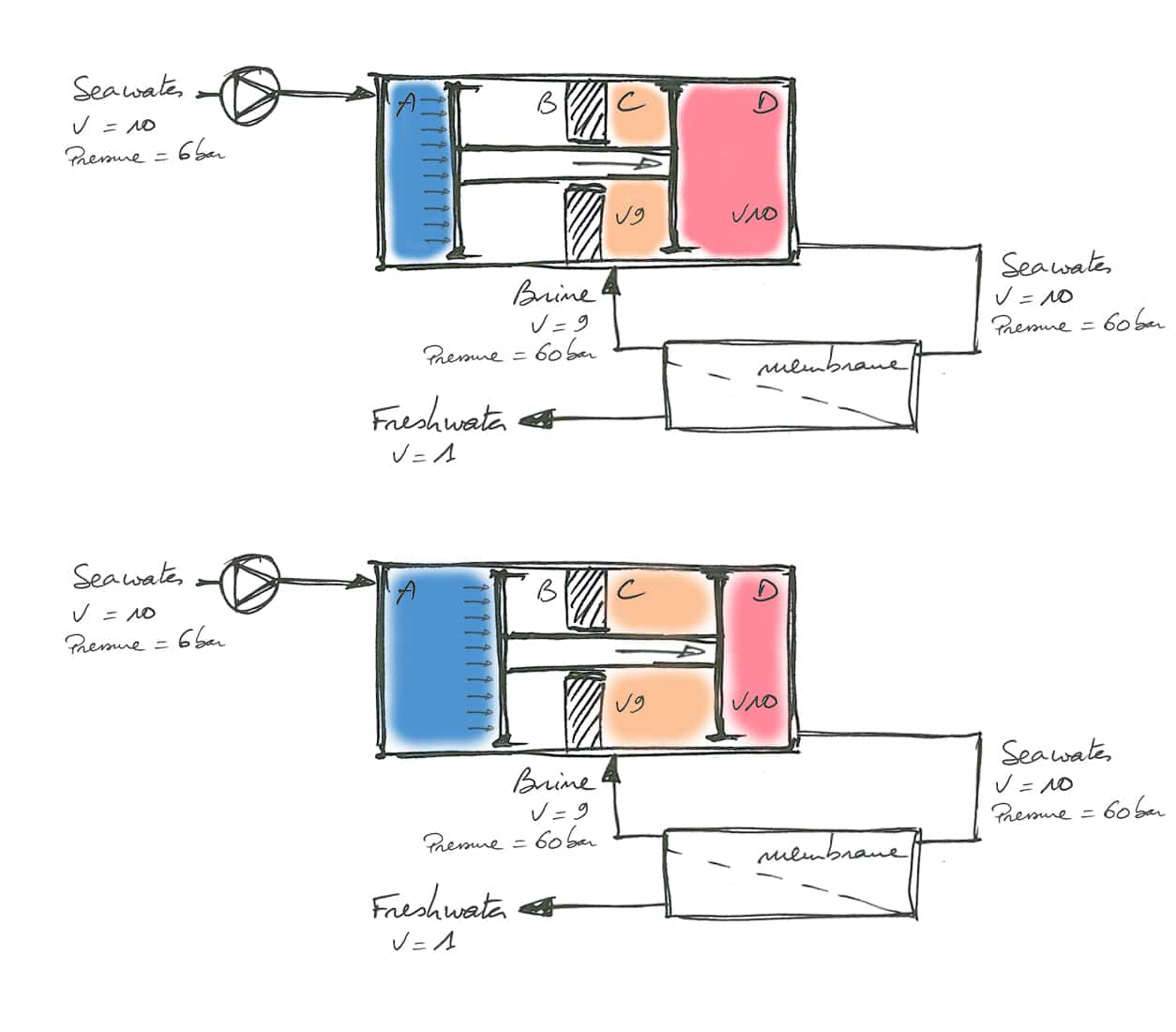

The booster pump provides pressure to the linear ERD. This pressure is progressively multiplied up to 60 bar by a section ratio in order to supply the membrane.

The discharge of 9 volumes under pressure from the membranes are sent into chamber C. It thus contributes to the drive of the piston.

These 60 bar are obtained as follow:

- The pump supplies chamber A at a pressure of 6 bar. This pressure is applied on a surface of 10. That is an overall effort of 10×6 = 60. (Force = Section x Pressure)

- After several cycles, the reject of the membrane feeds chamber C at a pressure of 60bar on an a section of 9. That is to say an overall force of 9 × 60 = 540

- The combined forces coming from chamber A and chamber C, ie 540 + 60 = 600, is transferred to chamber D. The latter having a surface area of 10, this represents 10 volumes at 60 bar (10 × 60 = 600)

Once the piston has reached the end of its stroke, a distribution system makes it possible to reverse the stroke. Now :

- The sea water feeds chamber D

- The membrane is connected between chambers A and B

- Brine in chamber C is discarded

Units equipped with this type of linear E.R.D. consume less than 150W for a production of 35L/h, compared with 375W for a conventional system.

This linear E.R.D. developed by SLCE watermakers is certified by Bureau Veritas.

In addition to its excellent energy performance, it is characterized by its acoustic and vibratory discretion.